The application of prefabricated bathrooms in prefabricated construction

As a transformation of traditional construction methods, prefabricated buildings are conducive to comprehensively improving the quality of construction and raising the overall level of construction, enabling the comprehensive quality and performance of buildings to be improved. They are also beneficial to promoting energy conservation, emissions reduction, and environmental protection in the construction industry, reducing carbon emissions, lowering dust and noise pollution, improving urban environments, and advancing the construction of ecological civilization. Therefore, from the State Council to local governments, efforts are being made to vigorously develop prefabricated buildings and continuously increase the rate of construction assembly. Prefabricated bathrooms, as an important component, are also increasingly widely used in prefabricated buildings.

The advantages of prefabricated bathrooms

Clean and dry: Prefabricated bathrooms are designed with rounded corners and no dead angles, and the surface of the waterproof tray has a good water slope and quick drainage. They do not accumulate water or absorb moisture, making them easy to clean and keeping the bathroom dry.

Extremely durable: The material of prefabricated bathrooms is compact and has a smooth and polished surface, which can effectively inhibit the growth of bacteria and keep the bathroom space looking new for a long time.

No leaks, no need for waterproofing: The chassis of prefabricated bathrooms is formed in one go by CNC machine tools, with high precision and good stability. This fundamentally eliminates the quality problems such as water leakage and seepage caused by manual work in traditional bathrooms, truly achieving a leak-free design.

Easy installation: Prefabricated bathrooms are constructed using dry methods and do not require traditional construction materials such as sand and cement. During installation, only materials such as screws and adhesives are needed. Generally, only two workers can complete the assembly in 4-8 hours, greatly reducing construction time and difficulty, as well as the amount of construction waste generated, which plays a great role in environmental protection.

A comparative analysis of prefabricated bathrooms with different materials

Prefabricated bathrooms are mainly divided into four categories according to their materials, namely SMC integrated bathrooms, VCM color steel plate integrated bathrooms, ALU functional integrated bathrooms, and thin-backed integrated bathrooms.

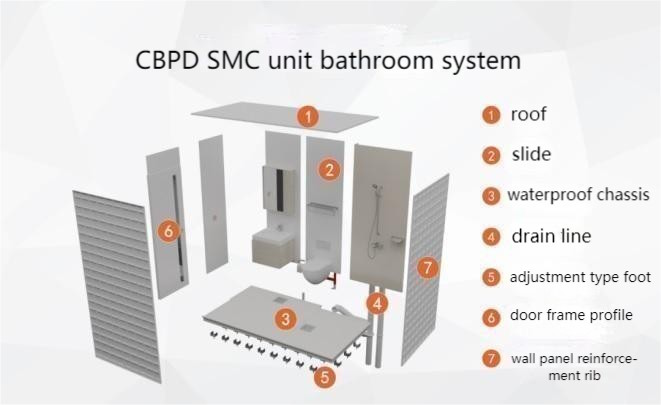

SMC integrated bathrooms

SMC (sheet molding compound) is an aviation composite material composed of chemically thickened unsaturated polyester resin, fillers, and glass fiber-reinforced materials.

The SMC chassis of the assembled bathroom is formed by a large mechanical high-temperature one-time molding, with a high degree of mechanization, guaranteed quality, good anti-slip performance, good thermal insulation performance, and no icy feeling.

The advantage of SMC wall panels is that they are lightweight, corrosion-resistant, and have a long service life. They have good thermal insulation performance, high density, smooth surface, no micropores, easy to clean, do not hide dirt, and effectively inhibit bacterial reproduction. The price of SMC integral bathroom is relatively cheap, suitable for ordinary hotels, hospitals, elderly care projects, and affordable housing.

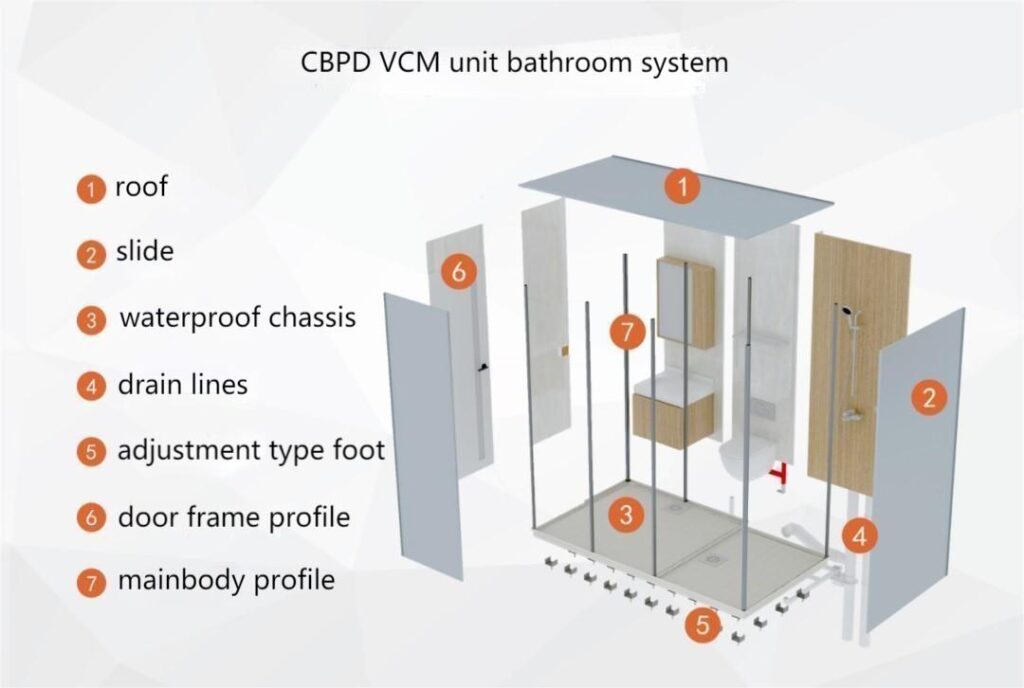

VCM integral bathroom

VCM integral bathroom is a steel plate composite material with an organic coating, environmentally friendly, pollution-free, corrosion-resistant, and easy to process and shape with the original strength of the steel plate.

ALU Functional Integrated Bathroom

The ALU medical aluminum bathroom system uses a flexible custom waterproof chassis and offers a wide selection of wall panels with multiple decorative textures to meet various style demands. It innovatively achieves the separation of bathroom functions, integrates the inner and outer walls, features integrated lighting, and has a flat floor with a gentle slope for water drainage.

Its advantages are high strength, good sound insulation effect, stable texture, rich colors, and diverse patterns, which can well meet the needs of consumers. It is suitable for high-end hotels, medical and elderly care, and boutique residences.

The high quality, low energy consumption, and low pollution of prefabricated bathrooms are in line with the sustainable development concept advocated by the country. Moreover, with the comprehensive development of prefabricated buildings in China and the increasing demand of customers for high-quality finished decoration, prefabricated bathrooms will receive great policy benefits and have a very broad industry prospect. The key to gaining consumer recognition lies in how to further reduce product costs, improve product quality, and meet the diverse and practical needs of users.