As we all know, a building constructed by assembling prefabricated parts in the factory and then on-site is called a prefabricated building. With its advantages of high efficiency, low cost, and low pollution, the prefabricated construction model is gradually being applied in hospital construction. Prefabricated decoration can directly reflect the final effect of prefabricated building design and construction, which directly affects the experience of patients and medical staff in hospital environments, and plays an important role in the prefabricated hospital construction industry.

Traditional construction methods have reached a bottleneck. The policy and market are oriented towards the modernization of green medical and care environments. With the continuous development of modern industry, lightweight materials, assembly processes, and integration have gradually become the trend of interior decoration in medical and care buildings. This trend will become more apparent as the construction industry progresses. CBPD Technology’s prefabricated interior system includes prefabricated high-sound insulation partition walls, prefabricated wall systems, dry floor systems, prefabricated bathroom systems, etc. It adopts standardized production and modular installation, with a factory prefabrication rate and on-site assembly rate of up to 80%, significantly improving construction efficiency and shortening construction periods.

Enhanced high-sound insulation partition wall system

To address problems such as the traditional wall chiseling for pipeline installation, poor sound insulation performance, high load, poor adaptability, and low installation efficiency, an innovative lightweight steel keel structure has been developed to improve sound insulation performance. The wall adopts a unique four-cavity sound insulation structure, adds damping sound insulation board, and sets up pipeline holes, achieving the integration of pipeline, bottom line box, and wall installation, improving the sound insulation performance of the wall, solving the problem of sound transmission, enhancing the wall strength, installation efficiency, and achieving the integration of wall, pipeline, and decoration.

ALU functional integrated partition wall system

Combining the material properties and changing the form of the keel structure, the plug-in method is integrated with the main structure of the keel to effectively deal with waterproof and airtight issues at the joints between the panels. The aluminum alloy has good antibacterial and corrosion resistance properties, as well as a stable load-bearing structure and flexible assembly methods, which enable the equipment to be installed on the wall, integrate functions, integrate pipelines, and provide open storage. This system is suitable for spaces that require high integration of pipeline equipment.

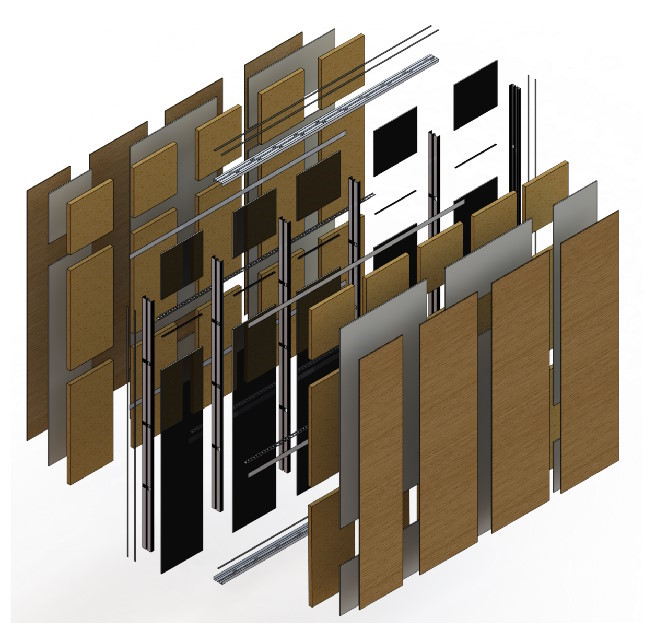

Integrated wall decoration system

On the basis of existing brick partition walls and household walls, the assembly-type installation of dry-decorative wall panels replaces traditional wet operations for wall surfaces. By connecting the profile keel uprights with the top and bottom keels, the wall panels are directly hung on the profile keels to form an integrated decorative wall system, which improves efficiency, accuracy, and quality.

Prefabricated-type integrated ceiling system

Integrate standard specification modular units of ceilings, electrical equipment, curtain boxes, and other systems for integrated installation. Ceiling materials can be selected from silicon crystal panels, mineral wool panels, aluminum panels, etc.

Prefabricated-type dry-floor raised system

The floor cavity is used for laying pipelines, leveling ground anchor bolts, providing high-strength load-bearing capacity, and good sound insulation. The system can also accommodate dry-floor heating modules and decorative layers such as wooden flooring, carpets, resilient flooring, and ceramic tiles.

The prefabricated-type functional module system

The Prefabricated-type functional module system is designed in a standardized way and assembled in a factory to form modules such as door and window modules, toilet modules, shower modules, wall cabinet modules, etc. This system improves efficiency, shortens the construction period, optimizes configuration, and enhances quality.